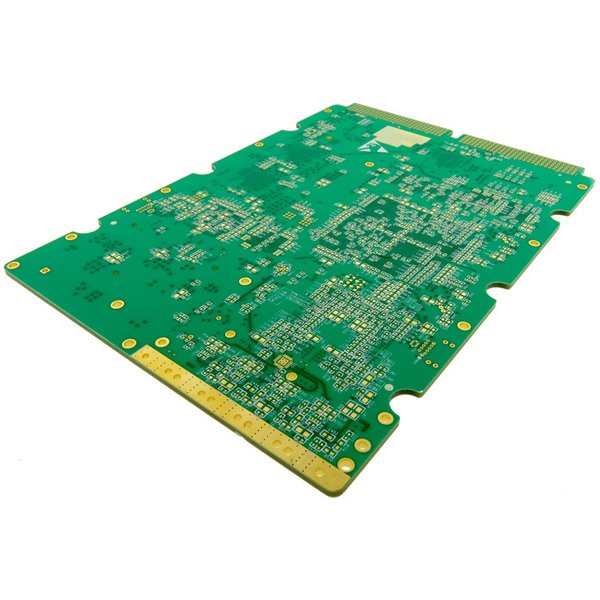

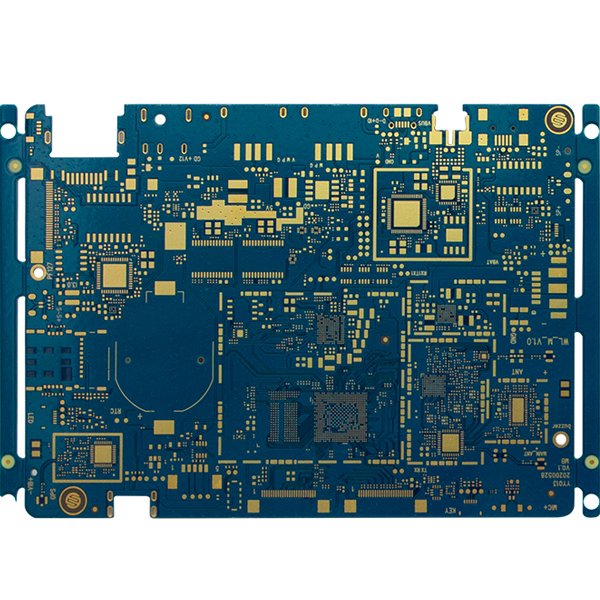

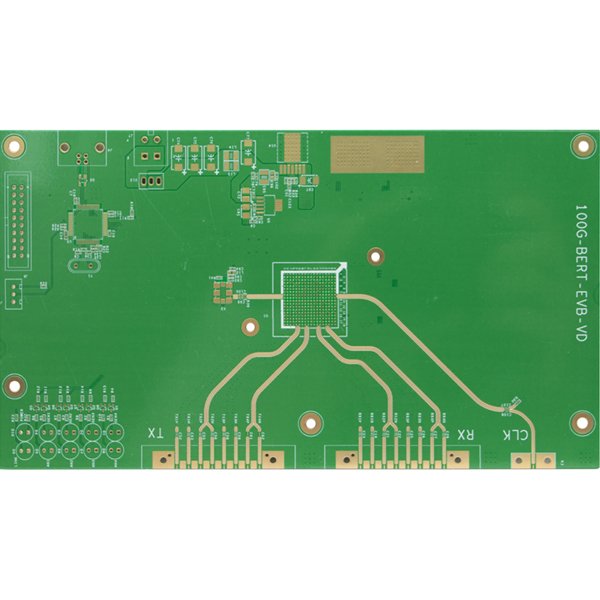

High Frequency Millimeter-wave PCB: Industrial IoT

In the rapidly evolving landscape of Industrial Internet of Things (IIoT), high frequency millimeter-wave (mmWave) printed circuit boards (PCBs) are emerging as a game-changing technology. These advanced PCBs are paving the way for unprecedented connectivity, data transfer speeds, and precision in industrial applications.

The Rise of mmWave PCBs in IIoT:

Millimeter-wave technology, operating in the frequency range of 30 GHz to 300 GHz, is becoming increasingly crucial in IIoT implementations. The adoption of mmWave PCBs is driven by several factors:

1. High Bandwidth: mmWave PCBs support massive data throughput, essential for real-time industrial monitoring and control.

2. Low Latency: The high frequencies enable near-instantaneous communication, critical for time-sensitive industrial processes.

3. Improved Precision: mmWave technology offers superior spatial resolution, enhancing location tracking and sensing capabilities in industrial environments.

4. Compact Design: Despite their high performance, mmWave PCBs can be designed with smaller form factors, ideal for space-constrained industrial settings.

Applications in Industrial IoT:

The integration of mmWave PCBs in IIoT is transforming various industrial sectors:

- Smart Manufacturing: High-speed, low-latency communication enables real-time process control and predictive maintenance.

- Warehouse Automation: Precise location tracking and high-bandwidth data transfer support advanced robotics and inventory management systems.

- Industrial Safety: mmWave sensors provide accurate personnel tracking and hazard detection in challenging industrial environments.

- Quality Control: High-resolution imaging capabilities of mmWave technology enhance non-destructive testing and inspection processes.

Design Considerations:

1. Signal Integrity: Careful attention to impedance matching, via design, and signal routing is crucial to minimize signal loss and distortion.

2. Thermal Management: High-frequency operation can lead to increased heat generation, necessitating effective thermal design strategies.

3. EMI/EMC Compliance: Proper shielding and grounding techniques are essential to meet electromagnetic compatibility standards in industrial environments.

4. Manufacturing Precision: Tight tolerances and advanced fabrication techniques are required to ensure consistent performance at mmWave frequencies.

Despite these challenges, the future of mmWave PCBs in IIoT looks promising. Ongoing research and development are focused on:

--- Advanced materials with improved dielectric properties

--- Novel antenna designs for enhanced signal propagation

--- Integration of AI and machine learning for adaptive mmWave systems

As these technologies mature, we can expect to see even greater integration of mmWave PCBs in IIoT, driving the next wave of industrial automation and efficiency.

High frequency millimeter-wave PCBs are set to play a pivotal role in shaping the future of Industrial IoT. Their ability to support high-bandwidth, low-latency communication while offering improved precision and compact design makes them an ideal choice for advanced industrial applications. As the technology continues to evolve, mmWave PCBs will undoubtedly become a cornerstone of the smart factories and industrial systems of tomorrow.