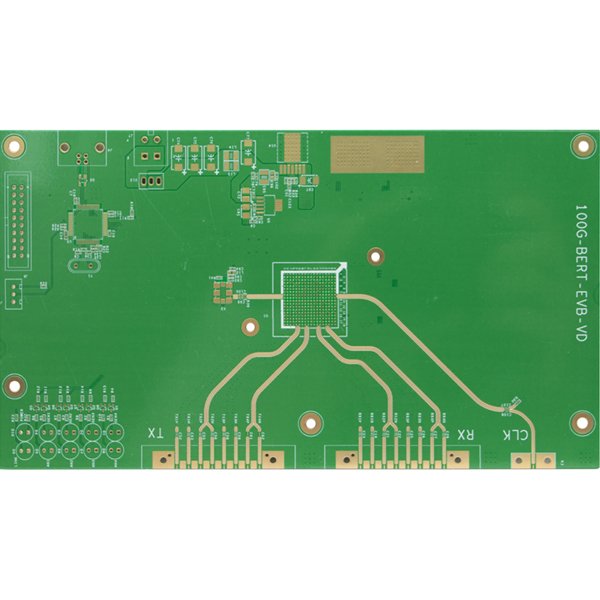

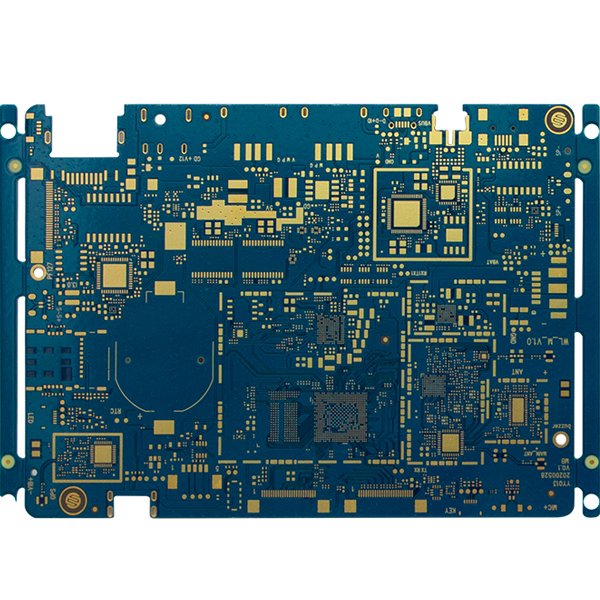

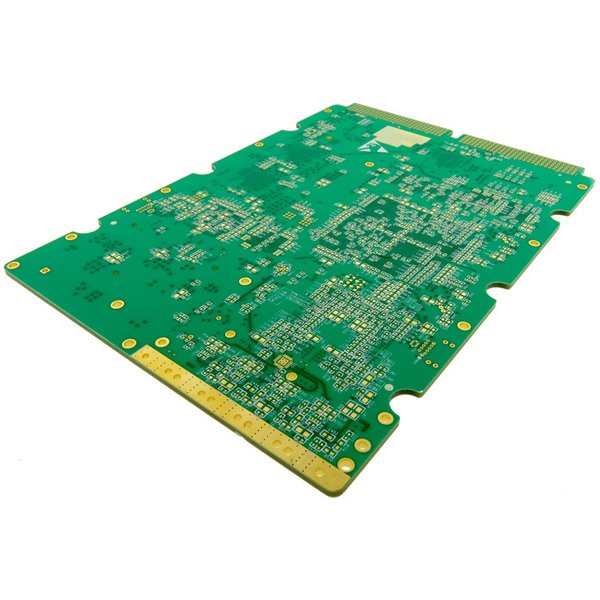

RF Millimeter-wave PCB

High frequency millimeter-wave PCB is composed of high-frequency circuit and the control circuit into a single unit. In addition, although high-frequency materials (PTFE, LCP, PPE, Low-k Epoxy) are more expensive than ordinary substrate materials.

PCB Material Stock:

We have the top suppliers like Rogers, Arlon, Nelco, and Taconic to meet the needs of RF PCB applications. We stock Rogers (4003 & 4350 series) and Arlon materials, which allows us to respond quickly—something few companies can do due to high inventory costs.

High-frequency PCBs are challenging to design due to sensitive signals and thermal management issues. Materials with low thermal conductivity are better suited for these designs than standard FR-4.

RF and Millimeter-wave signals require tighter impedance control. Using ground planes and proper trace design improves performance. Materials with higher dielectric constants (Dk) also allow for smaller PCBs. Often, high-Dk laminates (Dk 6 or higher) are combined with FR-4 in hybrid designs.

Understanding factors like thermal expansion, dielectric constant, and dissipation factor is crucial to creating reliable RF PCB designs.

RF PCB Material Types:

We work with various RF PCB materials, each offering unique benefits:

- Ceramic-filled PTFE composites: Known for their electrical and mechanical stability, Rogers RO3000 series materials maintain consistency across different dielectric constants (Dk), supporting multi-layer designs without warping or reliability issues.

- Taconic RF series: Offers low dissipation factor and high thermal conductivity, preventing oxidation, yellowing, or changes in Dk over time.

- Megtron 6: This ultra-low-loss, heat-resistant, halogen-free material has a high glass transition temperature (Tg) and is ideal for High-Density Interconnect (HDI) and high-speed designs above 3 GHz.

- Woven Glass Reinforced PTFE laminates: More dimensionally stable than other PTFE options, Taconic TL materials are perfect for radar and millimeter-wave antennas, especially at 77 GHz.

- Hydrocarbon ceramic laminates: Used for microwave and millimeter-wave designs, Rogers RO4000 series offers a wide range of Dk values (2.55-6.15) and good thermal conductivity.

- Filled PTFE composites: Rogers RT/duroid® materials are known for low electrical loss, moisture absorption, and outgassing, making them ideal for space applications.

- Thermoset microwave laminates: Rogers TMM materials provide excellent reliability with low Dk variation, copper-matched thermal expansion, and great mechanical strength, suitable for strip-line and micro-strip applications.

Application Areas:

- 5G/6G Base Stations

- Automotive Radar Systems (24 GHz, 77 GHz, 79 GHz)

- Satellite Communications

- High-Speed Data Centers

- Industrial IoT Sensors

- Aerospace and Defense

Our mmWave PCBs are meticulously designed and manufactured to ensure optimal signal integrity, minimal insertion loss, and exceptional reliability in high-frequency applications. With advanced materials and precise fabrication techniques, we deliver superior performance for your most challenging RF projects.