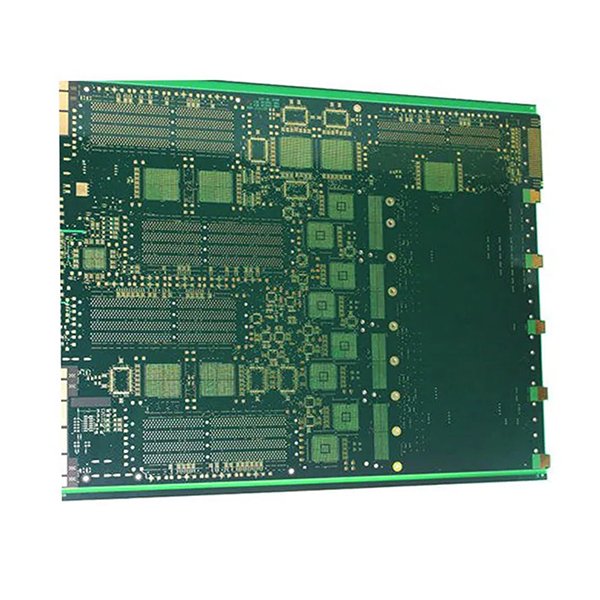

8L Microwave PCB Isola Astra MT77

Overview

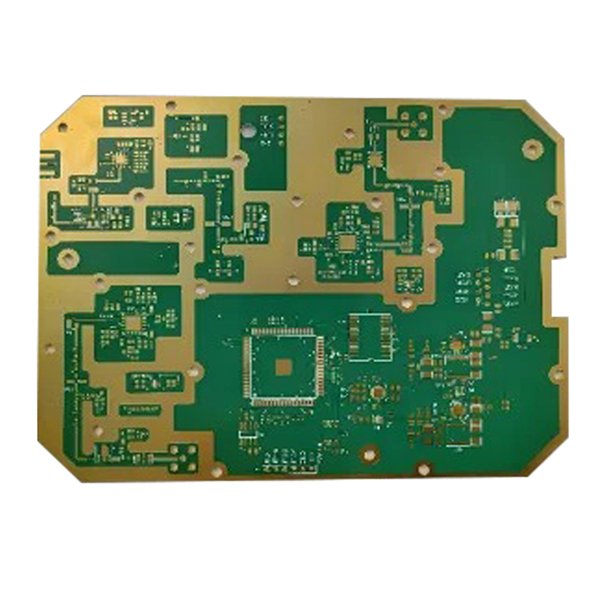

Microwave printed circuit boards (PCBs) are specialized substrates optimized for use at microwave frequencies, typically defined as signals exceeding 1 GHz. This technology plays a crucial role in facilitating high-frequency wireless communications, radar systems, electronic warfare, and testing equipment, operating effectively at millimeter wave frequencies up to 100 GHz.

Benefits of Microwave Printed Circuit Boards

Utilization of Low-CTE Materials: These materials help stabilize PCBs in high-temperature conditions.

Flawless Layer Alignment: Ensures a smooth and precise alignment of various layers.

Alignment of Multiple Layers: Low CTE materials facilitate the alignment of numerous layers within intricate structures.

Reduced Assembly Costs: Helps lower overall production expenses.

Enhanced Performance: Delivers optimal functionality.

Better High-Frequency Signal Transmission: Improves the efficiency of signal transmission at high frequencies.

Supports More Complex Designs: Allows for the creation of intricate and sophisticated designs.

Microwave PCB Fabrication and Assembly

The creation of microwave printed circuit boards involves sophisticated manufacturing techniques and assembly methods:

Material Evaluation: Properties such as dielectric constant and loss tangent are thoroughly assessed on production panels to ensure quality.

Surface Treatment: Oxide treatments and chemical preparations are employed to improve copper adhesion.

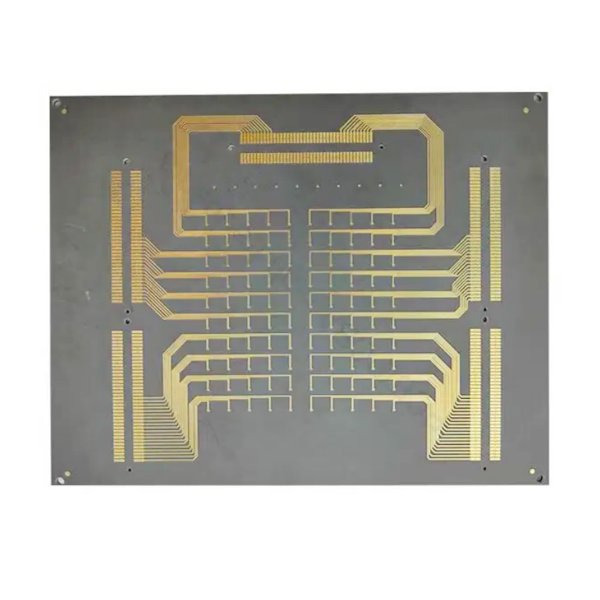

Etching Techniques: Conductors are formed using printed, plated, or etched methods to achieve intricate designs with smooth contours.

Layer Alignment: Precise alignment during layer stacking and lamination minimizes parasitic effects.

Hole Quality Assurance: Drilling techniques ensure high-quality hole walls for dependable plated via connections.

Solder Mask Application: A photoimageable mask offers excellent spatial accuracy for enhanced component placement.

Pad and Gap Specifications: Conductor layouts are precisely matched to chip terminations within micrometer tolerances.

Plating Supervision: Stringent control over plating thickness and hole filling maintains consistent electrical performance.

Automated Evaluation: Comprehensive electrical testing verifies impedance, signal propagation, and resonant frequencies.

Controlled Assembly Processes: Surface Mount Technology (SMT), wire bonding, and conformal coating are executed according to established protocols.