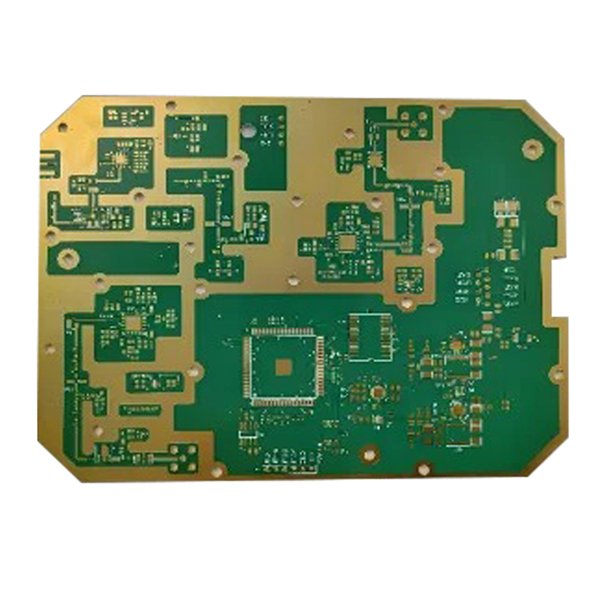

4L Microwave PCB Arlon CLTE-XT

What are Materials Used in Microwave PCBs?

The choice of substrate material is critical in microwave PCB design. Common materials include:

1. Rogers RO4000 series: Low-loss, temperature-stable materials

2. Taconic RF-35: High-frequency laminates with low dielectric constant

3. Isola Astra MT77: High-performance materials for millimeter-wave applications

4. Arlon CLTE-XT: Low-loss materials with excellent thermal stability

Here's a comparison of some popular microwave PCB substrate materials:

Material | Dielectric Constant | Dissipation Factor | Frequency Range |

Rogers RO4350B | 3.48 | 0.0037 | Up to 40 GHz |

Taconic RF-35 | 3.50 | 0.0018 | Up to 77 GHz |

Isola Astra MT77 | 3.00 | 0.0017 | Up to 100 GHz |

Arlon CLTE-XT | 2.94 | 0.0012 | Up to 110 GHz |

Key Points in Microwave PCB Manufacturing

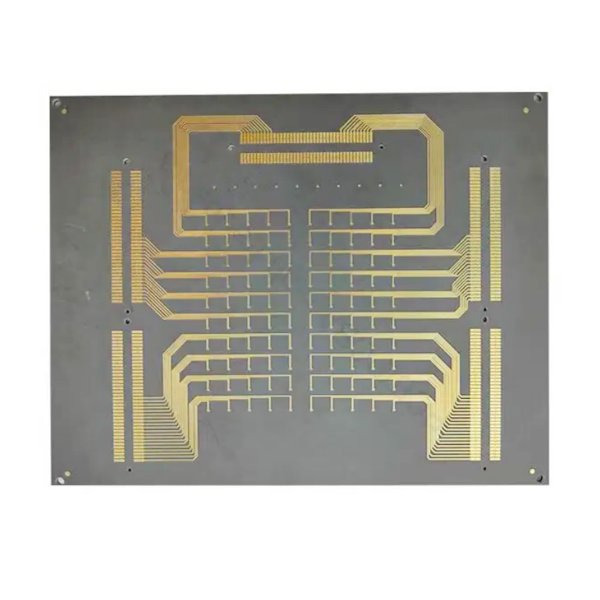

Etching Techniques

Accurate etching is vital for microwave PCBs to ensure precise trace widths and spacing. Advanced etching methods include:

1. Laser Etching: Provides high precision for intricate features.

2. Chemical Etching: Effective for larger features and lower frequency applications.

3. Plasma Etching: Delivers clean, precise edges ideal for high-frequency uses.

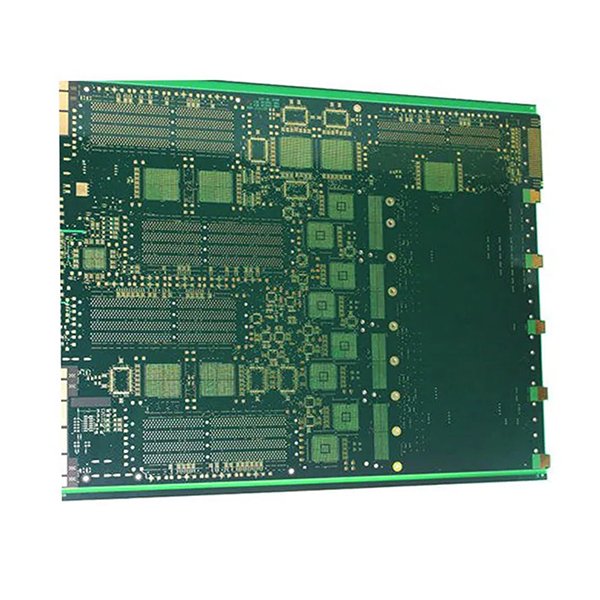

Lamination and Bonding

The lamination process is essential for preserving the integrity of the substrate material and ensuring proper adhesion between layers. Important factors to consider include:

1. Temperature Control: Helps prevent warping and maintains material properties.

2. Pressure Uniformity: Ensures consistent bonding throughout the board.

3. Vacuum Lamination: Eliminates air pockets and enhances layer adhesion.

Drilling and Via Formation

Vias are crucial in microwave PCBs for grounding and connecting layers. Advanced drilling methods include:

1. Laser Drilling: Ideal for small, high-aspect-ratio vias.

2. Mechanical Drilling: Suitable for larger vias and through-holes.

3. Back-Drilling: Removes unused sections of plated through-holes.

Plating Processes

Plating is key for forming conductive vias and enhancing surface conductivity. Common plating methods include:

1. Electroless Copper Plating: Provides the initial layer for via walls.

2. Electrolytic Copper Plating: Increases copper thickness.

3. Nickel and Gold Plating: Used for surface finishes and improved conductivity.