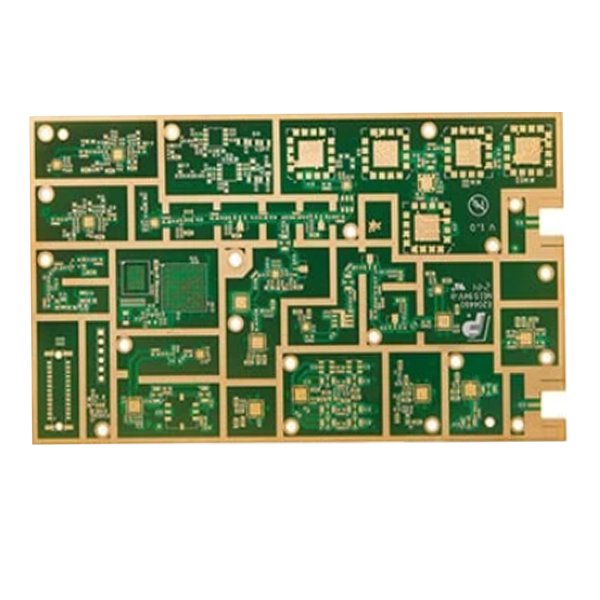

12L Radio Frequency PCB Rogers RO 4350B

What are Main RF PCB Materials Suppliers?

Material selection is an integral component of a successful RF printed circuit board.

Isola

Isola focuses on designing and manufacturing copper-clad laminates and dielectric prepregs used in multi-layer PCB fabrication. The company’s materials are used in many applications and markets, including networking, communications, radio frequency, and microwave.

Rogers

Rogers manufactures high-frequency laminates, bondplys, and prepregs. The company’s specialty materials, which have excellent dielectric constant control, are ideal for 5G wireless communication, automotive radar sensors, aerospace applications, and satellites.

Arlon

Arlon specializes in polyimide, low flow, and epoxy products; high TF multifunctional epoxy, controlled thermal expansion, low loss thermoset laminate and prepeg systems; and surface-mount technology. Typical applications for these materials include advanced commercial and military electronics.

Taconic

The company provides advanced composite materials for microwave, RF, and high-speed digital applications, including telecommunications.

Panasonic

The electronics materials division of Panasonic manufacturers Megtron high-performanced PCB and flex materials.

Nelco

Many of Nelco's materials provide high thermal reliability and conductive anodic filament (CAF) resistance for lead-free assembly compatibility. The company's materials are designed for high layer count PCBs and high-speed digital applications, including communications and networking equipment.

DuPont

DuPont manufactures Pyralux and high temperature flex materials; flex circuits are used in the oil, automotive, military, aerospace, and healthcare industries, in addition to many consumer products.

Key Points in RF PCB Manufacturing

High-Frequency Signal Handling: The manufacturing process is specifically designed to meet the requirements for managing high-frequency signals effectively.

Substrate Material Selection: The process begins with choosing the right substrate materials, commonly including FR4, Teflon, and specialized ceramics. RF PCBs are designed to optimize performance by minimizing signal loss and electromagnetic interference (EMI).

Precision in High-Frequency Production: The manufacturing steps for RF PCBs mirror those of standard PCBs, including copper cladding, photoresist application, photolithography, etching, drilling, plating, and surface finishing.

Quality Assurance: After production, the finished RF PCBs undergo rigorous testing and inspection to identify any defects. The entire sequence of manufacturing processes ensures that the final product can handle high-frequency applications, ranging from hundreds of megahertz (MHz) to several gigahertz (GHz).