The Role of High-Frequency PCBs in the Medical Industry

High-Frequency Printed Circuit Boards (PCBs) play a pivotal role in contemporary medical technology. These sophisticated components are essential for facilitating rapid data transmission, preserving signal integrity, and ensuring precision in challenging medical environments. As healthcare technology continues to advance, the demand for high-performance PCBs capable of supporting cutting-edge diagnostic and therapeutic systems is experiencing exponential growth.

This article examines the diverse applications and critical importance of high-frequency PCBs within the medical sector, elucidating how these specialized circuit boards have revolutionized modern healthcare practices. We will explore the unique characteristics that make these PCBs indispensable in medical devices and analyze their impact on patient care and treatment outcomes.

--- Key Properties of High-Frequency PCBs

High-frequency PCBs are designed to operate at frequencies typically above 1 GHz. These boards are constructed using specialized materials such as PTFE (Teflon), Rogers, and ceramics to maintain signal integrity, minimize signal loss, and reduce interference, which are critical in sensitive medical applications.

Some of the key characteristics of high-frequency PCBs that make them suitable for the medical industry include:

- High signal transmission speed

- Low signal loss and distortion

- Enhanced heat resistance and reliability

- Precision and stability in high-frequency applications

Applications of High-Frequency PCBs in Medical Devices:

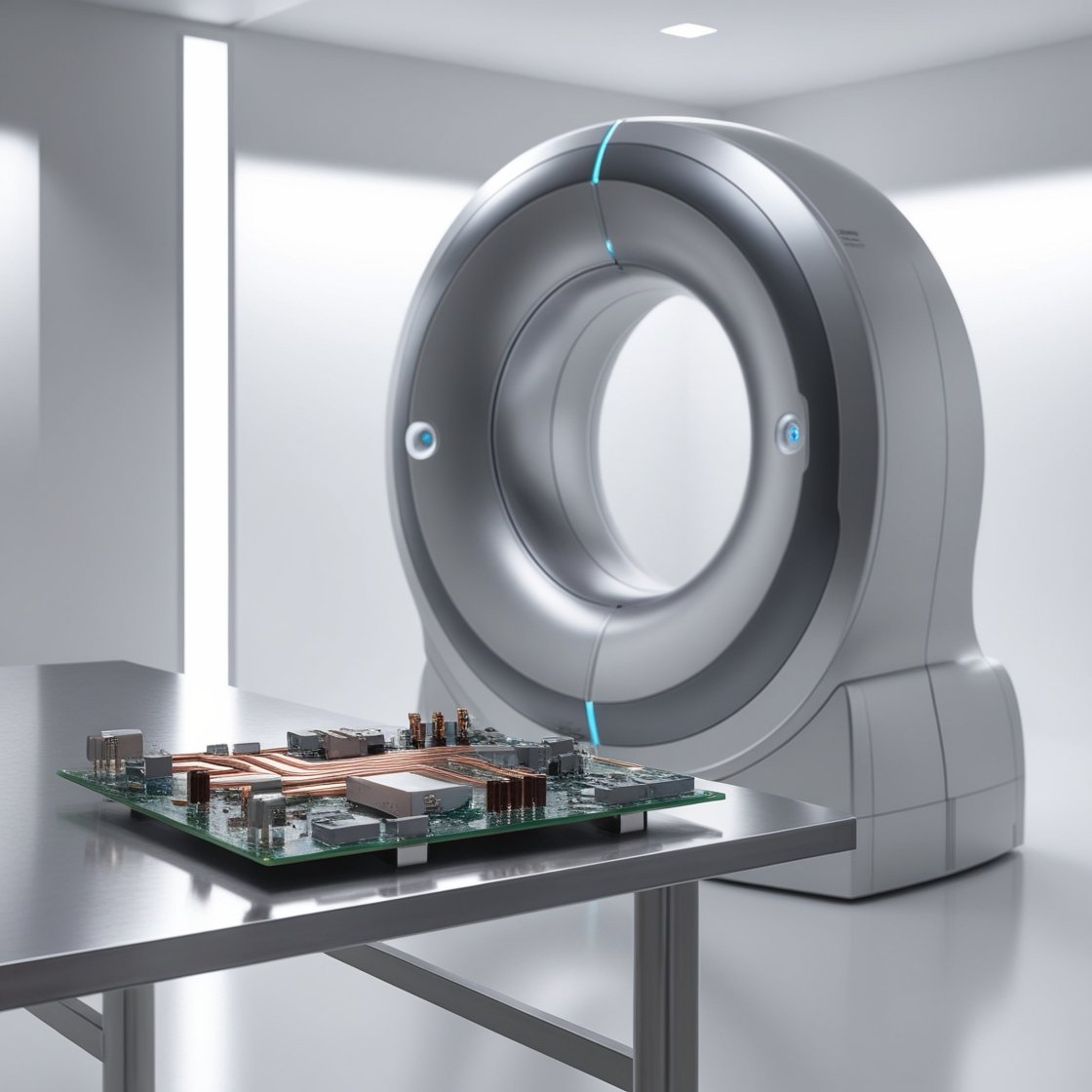

1. Magnetic Resonance Imaging (MRI) MachinesMRI machines are one of the most widely used diagnostic tools in hospitals and medical centers. These machines rely on strong magnetic fields and radiofrequency (RF) signals to generate detailed images of the body's internal structures. High-frequency PCBs are essential in controlling the RF signals that enable accurate image generation without interference, ensuring that the MRI machines function with high precision. |

|

4. Wearable Medical DevicesWith the rise of remote patient monitoring and telemedicine, wearable medical devices have become increasingly popular. Devices such as ECG monitors, insulin pumps, and smart health trackers often integrate high-frequency PCBs to ensure precise data collection and wireless communication. These PCBs enable the devices to operate at high frequencies while maintaining accuracy and reliability, even in miniature form factors. |

2. Computed Tomography (CT) ScannersCT scanners are used to create detailed cross-sectional images of the body, aiding in the diagnosis of various conditions. The electronics in these machines require rapid data transmission and high processing speeds, which are facilitated by high-frequency PCBs. These circuit boards help ensure that the images produced are clear and precise, enabling accurate diagnostic outcomes. |

|

5. Robotic Surgery SystemsAs robotic surgery becomes more prevalent, the need for highly reliable and accurate electronics increases. High-frequency PCBs are used in robotic surgical systems to enable precise control over the robotic arms and tools. The ability of these PCBs to handle high-speed data transmission and provide real-time feedback is essential for the success of minimally invasive surgeries. |

3. Ultrasound EquipmentUltrasound technology utilizes high-frequency sound waves to generate real-time images of soft tissues, organs, and blood flow within the body. The transducers in ultrasound machines, which convert electrical signals into sound waves, rely on high-frequency PCBs for optimal signal transmission. This allows for accurate imaging and diagnosis without distortion or delays. |

|

6. DefibrillatorsPortable defibrillators, both in hospitals and in public areas, depend on high-frequency PCBs to manage the electrical pulses that restore a normal heart rhythm during cardiac arrest. The precision and reliability of these circuit boards are critical in life-saving situations, ensuring that the devices perform as expected in high-stress environments. |

Advantages of High-Frequency PCBs in Medical Applications

--- Signal Integrity and Accuracy

In medical devices, accurate signal transmission is paramount. High-frequency PCBs reduce signal loss, distortion, and interference, ensuring that devices like MRI machines and ultrasound equipment provide precise readings.

--- Reliability and Durability

Medical devices are often used in critical environments where failures are not an option. High-frequency PCBs offer high reliability, with resistance to heat, moisture, and harsh conditions, ensuring that devices can function continuously without interruption.

--- Miniaturization

As medical devices become more compact and portable, high-frequency PCBs support the trend toward miniaturization. They allow for the integration of more advanced electronics into smaller form factors, making devices like wearable health monitors possible.

--- Future Prospects

With advancements in medical technology, the need for more efficient and higher-performing PCBs will continue to grow. High-frequency PCBs will play an even more significant role in supporting innovations such as AI-assisted diagnostics, advanced imaging systems, and remote healthcare solutions. The integration of 5G technology into medical devices will further increase the demand for PCBs capable of handling ultra-high frequencies and large data volumes.

High-frequency PCBs have revolutionized the medical industry by enabling faster, more accurate, and more reliable medical devices. From diagnostic imaging systems to wearable health monitors, these specialized circuit boards are integral to the functionality of modern healthcare technology. As the medical field continues to advance, the role of high-frequency PCBs will expand, contributing to better patient outcomes and more efficient healthcare delivery.

You can download this Article from here..

The Role of High-Frequency PCB

The Role of High-Frequency PCB

Medical Electronics Industry P

Medical Electronics Industry P