Differences Between RF PCB, Microwave PCB and Millimeter Wave PCBs

The ever-evolving landscape of electronics has led to the widespread use of high-frequency PCBs (Printed Circuit Boards) in various applications, particularly in telecommunications, aerospace, and medical devices. As the demands for faster data transmission and improved performance accelerate, it's essential to understand the distinctions between RF (Radio Frequency), Microwave, and Millimeter Wave PCBs. Each type serves unique purposes and operates within specific frequency ranges, necessitating tailored design considerations and materials.

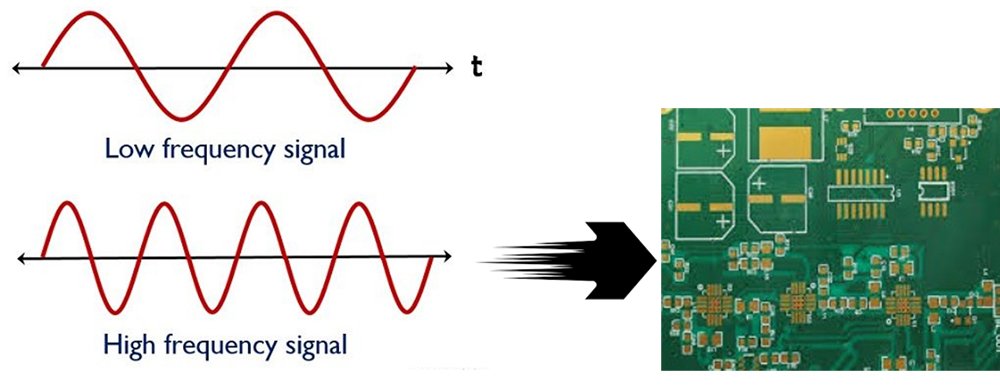

Defining Frequency Ranges

RF PCBs

Frequency Range: Typically from 3 kHz to 300 GHz.

RF PCBs are designed for applications such as radio transmission, satellite communications, and RFID systems. The RF range encompasses a broad spectrum, including low, medium, and high frequencies. These boards effectively handle signals that require varying degrees of complexity in design and material choice.

Microwave PCBs

Frequency Range: Typically between 300 MHz and 30 GHz.

Microwave PCBs are used in short-range communications, radar systems, and various industrial applications. This frequency range is crucial for technologies that require precise transmission and reception of signals. Microwave circuits are often more complex than standard RF circuits, necessitating more rigorous design and testing protocols.

Millimeter Wave PCBs

Frequency Range: Generally from 30 GHz to 300 GHz.

Millimeter Wave PCBs are at the cutting edge of technology, utilized in advanced applications such as 5G cellular networks, high-speed satellite communications, and automotive radar systems. The small wavelengths at these frequencies allow for significant bandwidth but also introduce challenges in terms of signal integrity and attenuation.

Key Differences

1. Signal Integrity and Transmission Loss

Signal integrity becomes increasingly crucial as frequencies rise. RF PCBs typically experience less signal loss due to larger wavelengths, while Microwave and Millimeter Wave PCBs face significant challenges with attenuation. Designers must account for transmission line properties, material losses, and environmental factors to ensure signal clarity.

2. Material Selection

The materials used in these PCBs vary based on their frequency:

RF PCBs: Common materials include FR-4 and Rogers 4003, which provide a balance between cost and performance.

Microwave PCBs: Materials like Rogers 4350 and Taconic TLY-5 are preferred due to their specialized dielectric properties that maintain performance.

Millimeter Wave PCBs: High-performance materials such as Rogers RO4003C or low-loss PTFE are essential to handle the high frequencies and maintain signal fidelity.

3. Design Considerations

Each type of PCB requires distinct design considerations:

RF PCB Design: May utilize simpler layout practices but must consider impedance matching and basic shielding to minimize interference.

Microwave PCB Design: Demands careful attention to transmission line design, impedance control, and dielectric losses, often incorporating advanced modeling and simulation.

Millimeter Wave PCB Design: Requires highly sophisticated techniques. Designers must consider the effects of parasitics in components, tight tolerance manufacturing, and in-depth electromagnetic simulations.

4. Applications and Uses

The applications for each type of PCB also highlight their differences:

RF PCBs: Found in radios, wireless communication devices, and broadcasting equipment.

Microwave PCBs: Essential for radar, satellite communication, and microwave ovens.

Millimeter Wave PCBs: Crucial for emerging technologies like 5G networks, automotive safety systems, and high-speed wireless communications.

Understanding the nuanced differences between RF, Microwave, and Millimeter Wave PCBs is vital for engineers and designers working in high-frequency electronics. Each category operates within specific frequency ranges and has distinct material requirements, design considerations, and applications. As technology progresses, mastering these differences will be increasingly important to harness the full potential of high-frequency communication systems, ensuring reliable and efficient performance in a competitive technological landscape.

By keeping these distinctions in mind, industry professionals can make informed decisions that enhance the capabilities and reliability of electronic devices, paving the way for future innovations.

The Evolution of PCB Technolog

The Evolution of PCB Technolog

Top 6 PCB Industry Trends Shap

Top 6 PCB Industry Trends Shap

Sustainable Materials and Manu

Sustainable Materials and Manu

The Impact of DeepSeek, NVIDIA

The Impact of DeepSeek, NVIDIA